| Title: | Zero Defect Manufacturing for Thermo-dynamical Processes |

|---|---|

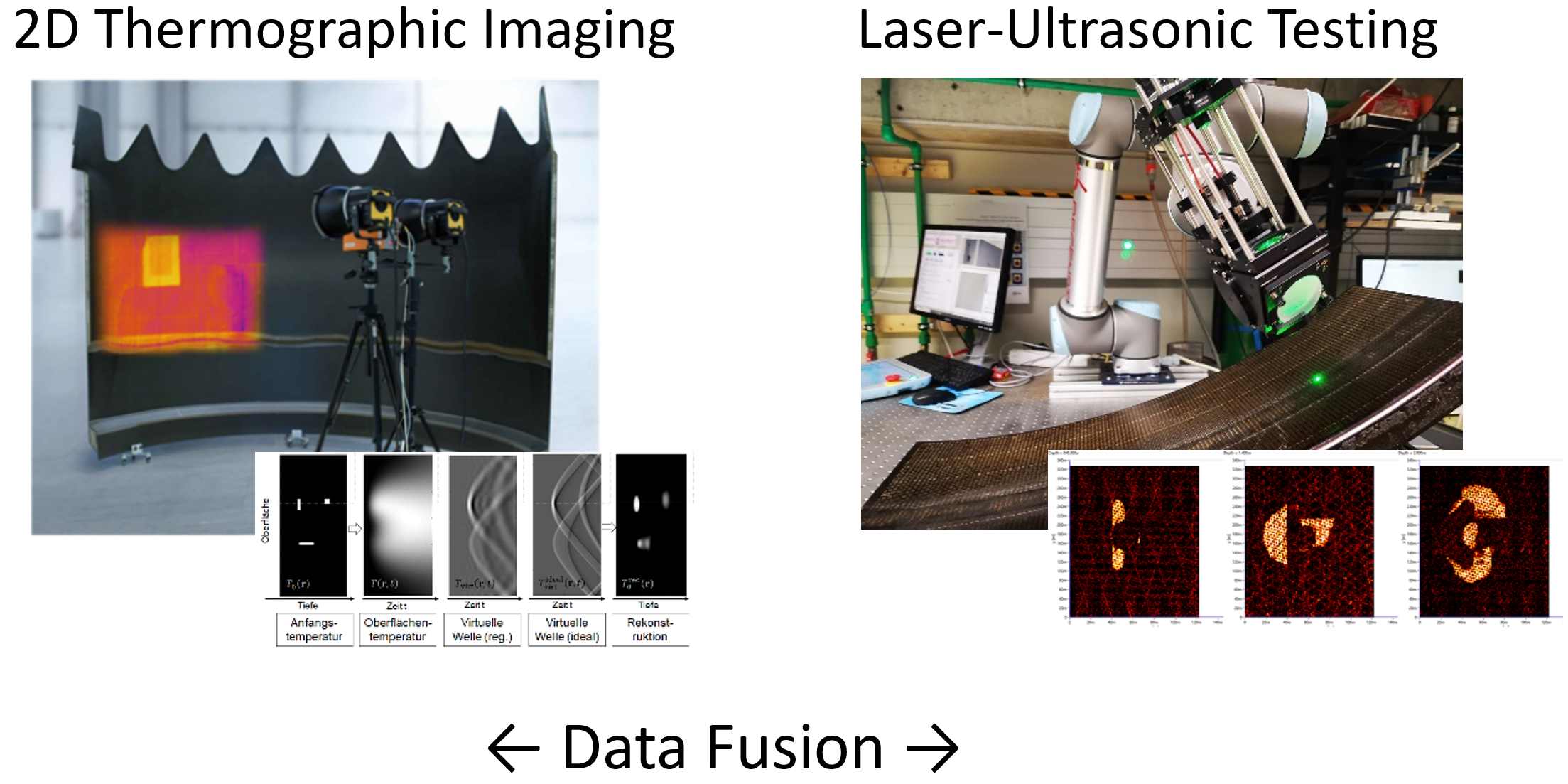

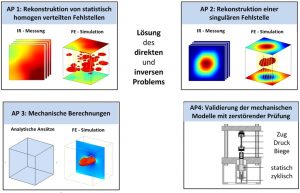

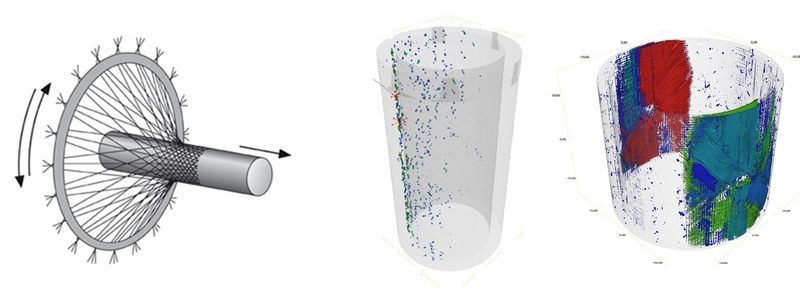

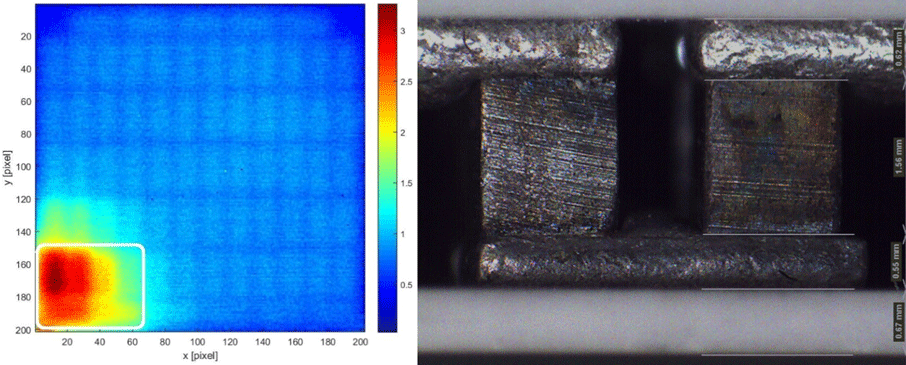

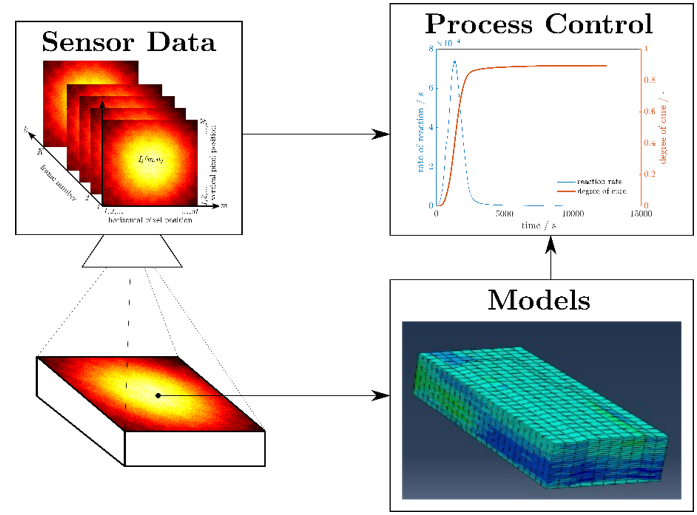

| Abstract: | The main objective of this research project is to develop a zero-defect manufacturing method for thermo-dynamical processes. The standard approach for such processes is to use experiments supported by simulation to find a suitable “recipe” and require in some cases comparably high safety margins to account for the remaining uncertainty. In the project sensors and data-driven models are developed, which allow an improved process control and reducing scrap material. Applications in the aerospace industry (composite parts), automotive industry (decorative parts) and extractive industry (aluminium production) are considered as case studies for the development. In these fields, process times can be shortened by 10-20% and scrap material can be reduced. |

| Consortium Leader: | Profactor GmbH |

| Duration: | 01.05.2021 to 30.04.2024 |

| Program: | Produktion der Zukunft (FFG) |