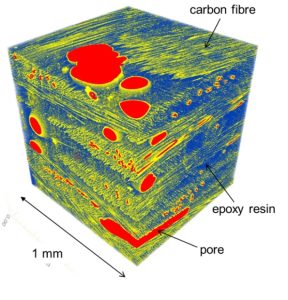

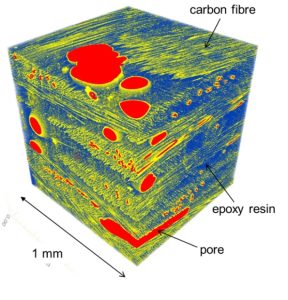

In this work active thermography was successfully applied as a quantitative method for the non-destructive evaluation of porosity in carbon fiber reinforced polymers. Results showed that not only the level of porosity, but also the shape of the pores strongly influences the active thermography results, in particular the measured thermal diffusivity. In an experiment the shape of the pores was obtained by means of X-ray computed tomography. Based on this microstructural information, the “dethermalization theory” can be deduced as the most effective thermal diffusivity model with respect to quantitative porosity determination.Furthermore, the obtained experimental data on active thermography correspond to measurements made using ultrasonic testing with respect to the influence of pore shapes. www.sciencedirect.com

Solar Cells can be characterized by means of a multitude of thermographic methods. The simplest approach is the generation of thermograms by Passive Thermography during the operation of solar modules. On such thermograms, local leakage currents (shunts), which deteriorate the electrical parameters of solar cells, may lead to contrasts, which can be evaluated in a qualtitative way. A much more sensitive approach to solar- cell-characterization can be achieved by means of various methods of Lock-In-Thermography (LIT). Thus local defects can be visualized, even those which could not be found with conventional Passive Thermography. In some cases also a quantitative evaluation is possible from LIT-results. On that bases images of shunts, series resistance, local I-V-curves or open Circuit Voltages can be generated. By means of Carrier Density Imaging it is possible to image the lifetime of the photo-generated carriers, which gives information about the local quality of solar cells, e.g. the distribution of impurities, which has a strong impact on the efficiency of solar cell modules.

A great advantage of all thermographic methods is, that they are a non-contact method and can be applied during the whole fabrication process. Therefore, thermographic methods can be used to control and optimize the parameters of solar cell fabrication.

We developed an experimental setup where a pulse of heat energy (pulsed laser) is applied to a target specimen (small cylindrical object made of steel or graphite), launching a thermal front which propagates into the specimen by thermal diffusion. We then use a high speed thermal camera to image the spatio-temporal temperature distribution (i.e. the spatial temperature distribution and the temporal evolution of temperature at different positions) of this ideal 1D-heat conduction process. This allows the imaging and analysis of very fast transient thermal processes (at the millisecond scale). Especially, the influence of ‘thermal barriers’ (=defects) can be studied in detail and according theoretical models can be experimentally verified.